Анодні заземлювачі ТДМ-АЦ, ТДМ-АЦ-КТ, ТДМ-АП/ Anodenerdung / Anodenelektrode (KATHODISCHER SCHUTZ)

Ціну уточнюйте

- В наявності

- Оптом і в роздріб

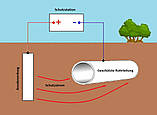

Основним напрямком науково-виробничої діяльності ТОВ «Дніпропетровська трубна компанія» є створення та впровадження ефективних нових, мало зношуються анодних заземлювачів для систем електрохімічного захисту від корозії нафто - газопроводів, сталевих споруд і об'єктів розміщених в грунті і під водою.

Дана продукція сертифікована, поставляється по ТУ У 24.4-31951266-001:2016, має сертифікат відповідності Державної системи сертифікації УкрСЕПРО, а також висновки санітарно-епідеміологічної експертизи про те, що вироби відповідають вимогам діючого санітарного законодавства України.

Ми пропонуємо анодні титан-диоксидмарганцевые заземлювачі наступних типів:

- циліндричні ɣ-ТДМ-АЦ, ɣ-ТДМ-АЦ-КТ і ɣ-ТДМ-АЦ-КТ-2;

- пластинчасті ɣ-ТДМ-АП.

- графітові

Нова технологія отримання анодних заземлювачів виключає використання дорогоцінних металів, забезпечує зниження трудомісткості і енергоємності операцій, дозволяє збільшити термін експлуатації газо-нафтопроводів в два-три рази, чим суттєво покращує техніко-економічні показники при серійному виробництві.

В даний час ТОВ «Дніпропетровська трубна компанія» володіє виробничою базою і необхідним технологічним обладнанням для серійного виготовлення анодів і збірок багатоелементних анодних заземлювачів глибинних і поверхневих видів з використанням надійно захищених герметично виконаних електричних з'єднань.

Dnepropetrovsk Pipe Company LLC has been founded in 2004. Our company's specialists developed and created high-tech anode beds (AB) for long-term electrochemical protection of oil and gas pipelines, storage facilities and other structures made of steel and in contact with aggressive environments, including salt water. The result of scientific and technical research was the creation of industrial technologies for the manufacture of new types of low-wear anodes based on valve metals - titanium and its alloys. Technical documentation was developed and Wear-resistant titanium dioxide-manganese anode beds in accordance with TU U 24.4-32905858-001: 2016" were manufactured.

For reference:

Low-wear AB γ-TDM-AC, γ-TDM-AC-KT, γ-TDM-AC-KT-2, made on a titanium base of a cylindrical shape with an anode-resistant coating of manganese dioxide (γ-MnO2, with a coating thickness of 60 microns), stand head and shoulders above known poorly soluble analogs based on graphite, ferrosilide, magnetite in their resistance, and are close to AB, coated with precious metals of the platinum group (platinum, ruthenium, iridium) or their oxide compounds - to the Mixed Metal Oxide group (IMO). As is known, sparingly soluble AB (ferrosilides and graphite-containing AB) are characterized by the “dissolution reaction of the anode material: Мо Моn+ + ne-» in other words, at every hour of work lose their mass and therefore lose their geometry and working area. This leads to a loss of performance: a decrease in the current load of the electrode and an increase in the spreading resistance to current AB. To get out of this situation, manufacturers of ferrosilide AB use alloying materials, dramatically increase the electrodes mass and overall dimensions of their AB. In the field, during the installation of AB, it is necessary to use lifting equipment and slings, which is not always possible. As rigging, installers begin to use current-conducting electrode cables. As a result, the quality of installation, and hence the durability of the AB life, drops sharply! Graphite-containing electrodes are additionally subject to "cold burning" and are very sensitive to soil moisture. Those, the reliability of the cathodic protection installation is largely determined by the materials of the anodes and their design. And heightened requirements are placed on the quality of installation works.

Since 2011, γ-TDM-type AC ABs were installed for pilot operation at the following sites: "Donetskgaz" PJSC, "Dneprogaz" PJSC, "Dnepropetrovskgaz" PJSC, "Lvovgaz" PJSC, "Zhytomyrgaz" PJSC, "Kievgaz" PJSC. Based on the experience gained in operating in various environments, multilevel insulation of the contact node of our ABs was further developed and applied. Current-carrying cables are made in one piece and are not cut into pieces at the entrance to the contact node. And the electrodes themselves, even in the factory, are mechanically connected by means of a load-carrying cable and equipped with a gas outlet pipe. The rated current load on one electrode of the γ-TDM-AC type is 4.5 A, the maximum is 9A. The electrochemical equivalent is 10,000 times lower than that of ferrosilide and graphite-containing electrodes, which in practice leads to a significantly smaller number of electrodes in the set, compared to competitors. AB design proposals is developed спільно with the "Customer" on the basis of the terms of reference for specific conditions. Below there is an example comparative table of electrodes in AB.

The required number of electrodes AB in for the arrangement of the ECP of the pipeline under a load of 15-30A

|

Electrode type |

AZFS Ferrosilide anode grounding rod |

AZK Complete anode grounding rod |

γ-TDM-AC |

|

Quantity, pcs |

24 |

15 |

8 - 10 |

|

Maximum current load per 1m2 , А |

15 |

10 |

100 |

|

The dissolution rate of the material (coating), kg/A per year |

0,5 |

0,5 – 1,2 |

0,0003 |

|

Service life years |

5-10 |

5-10 |

30 |

|

Disadvantages |

Oxide film formation, dissolves |

Fragile, "cold burning", dissolves |

- |

*Taking into account the design features the complete factory availability of the AB kit, light weight, manufacturability installation of work, the duration of the operation, the cost of the total operating costs of AB "γ-TDM-AC" is several times cheaper than that of competitors.

To date, γ-TDM-AC-MV type of ABs, located inside the protected facility have successfully passed tests at TatNIPIneft and are operated at Tatneft PJSC named after V. D. Shashin for ECP of technological pipelines and internal surfaces of the internal combustion engine in formation water with a salt content of up to 163 g/liter. At the offshore oil transshipment terminal of Tamanneftegab LLC (Black Sea), an ECP system based on anode earthing conductors of the γ-TDM-AC-MV-PT type for marine use is equipped.

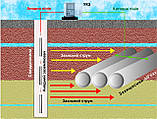

At present, pilot operation of the γ-TDM-AC type of ABs is being carried out to protect Ukrtransgaz JSC main gas pipelines in areas with sandy soil - ρg = 450. The number of electrodes is 12 pcs., current load is 22A, length of the gas pipeline to be protected, as per "GOST" requirements for protective potentials, is 3 strings*12 km (1 - D720mm, 2 - D1220mm, 3 - D1020mm). That is our 1m2 AB protects 3 pipelines with a total area of 111,000 m2.

The main competitive advantages of the γ-TDM-type AC ABs, which will allow your company to significantly reduce financial costs and increase the life of the ECP plant:

1. For the cathode station (1.5 kW, 48V, 30A), a number of sufficient electrodes of the anode bed in the kit is from 7 to 13 pieces (depending on the installation method of AB, electrical conductivity of the soil and state of pipeline insulation).

2. Low weight of the anode beds kit (15-100kg) allows to perform installation without the use of lifting and special equipment, which significantly reduces the cost of its installation and increases the service life.

3. The cost of the anode bed is lower than the cost of similar in properties anode bed of well-known manufacturers.

4. A wide range of current loads allows to reduce the number of electrodes in the set of the anode bed, which reduces its weight and cost, increases reliability due to a decrease in the number of contact electrical connections.

5. Block layout diagram of the anode bed allows, if necessary, to connect, disconnect (in case of an unexpected failure to reserve with a planned decrease in current load) individual blocks (groups of electrodes).

6. In the case of a deep installation option, the block layout scheme allows measuring resistance to AB spreading along the depth of the well.

7. Anode beds of the "γ-TDM-AC" type have no edge effect. It is possible to arrange a current-carrying cable and an electrical contact assembly in the internal cavity of the electrode with subsequent sealing.

8. High resistance of the anode coating in any type of soil, fresh and sea water. Dimensional stability and performance for long-term use.

9. Thickness of the combined coating of the electrodes of the anode ground electrode is from 60 microns to 300 microns (for particularly aggressive environments).

10. ABs are manufactured using environmentally friendly materials and comply with modern environmental standards.

11. ABs are manufactured in the factory, equipped with a load-carrying cable and a gas outlet pipe and delivered to the "Customer" fully ready for installation.

Titanium-based manganese dioxide coating is characterized by high catalytic activity and reduces the overvoltage of the anode process, on which the efficiency of the electric mode depends.

| Основні атрибути | |

|---|---|

| Країна виробник | Україна |

| Тип пристрою | Електрод |

| Товщина покриття | 100 мкм |

| Діаметр | 57 мм |

| Довжина | 500 мм |

| Вага | 1 кг |

| Гарантійний термін | 12 міс |

| Користувальницькі характеристики | |

| Виробник | Дніпропетровська трубна компанія, ТОВ |

- Ціна: Ціну уточнюйте